Winner Drawn: Update your details now and be in to win

UPDATE: 28th July 2017

Thanks to all the people who confirmed or updated their contact details with us recently, and went into the draw to win a sweet Davey Calf Milk Pump. The lucky winner was Michael Smith of Milky Whey Enterprises, who was pretty happy with his prize, saying “that’s ideal, stoked…”.

If you missed out you can still get yourself a Davey Mulitpurpose Vortex Pump (D15VA) for the bargain price of $190+GST – just give us a call on 0800 50 22 50 to order today.

Beat Jack Frost this winter with Pump Saver

For peace of mind during the winter, the Pump Saver has been designed to protect your pumps from frost damage.

How it works

The pump saver is designed to be left on all the time, so when the temperature drops, the lamp will come on automatically and give enough heat to protect the pump from frost damage. To increase frost protection, you can insulate the pump shed and lag pipes.

It's simple to install - all you need is a 230 volt power outlet to supply the pump saver.

Advantages

Cost savings:

- Protecting your pump from frost damage will save you money

- The pump saver only needs to save your pump once to pay for itself

- The heat lamp will only operate when the temperature drops to freezing or at a preset level (to heat a larger area we can supply a lead and thermostat that you can attached to a small heater for space heating, rather than spot heating)

- Maintenance costs could be reduced because the pump saver stops the pump from freezing up

Easy to install

- The pump saver can be installed by anybody, as long as there is a constant power source available. The heat lamp can easily be checked by dialing up the temperature on the thermostat

- Mount the pump saver thermostat on the wall alongside the pump, making sure the heat lamp is not shining onto the thermostat

- Hang the heat lamp above the pump using the hook and secure the cable ties as supplied. Keep at least 450mm away from surfaces

- Set the thermostat to 2oC and plug it into a contiuous power supply, making sure the plug is not controlled by a float switch or pressure switch as this would cause the heat lamp to only come on when the pump is running

Email andy.nesbit@nind.co.nz for further information or give us a call on 0800 50 22 50 to get your Pump Saver today.

Why should liners be changed regularly?

Most rubber liners are designed to last around 2500 milkings as they deteriorate with time and usage. Check out the information below on the importance replacing liners and why delaying this can affect the health of your herd and your bottom-line!

- Liners are the only part of the milking plant to come into contact with the cow's teats, so they can have a direct impact on the health of your cows.

- Liners are subject to a lot of wear and tear, opening and closing over 2.5 million times during its use, as they slacken the forces on the cow's teat increases along with the chance of liner slip.

- Liners are also exposed to harsh cleaning chemicals at high temperature, which over time can break down the rubber and milk deposits can be left on the surface.

- To the naked eye, a liner at 3000 milkings may look clean, but examination under microscope can show build-up and damage to the surface of the rubber.

- Studies show time and again that between 2000 - 3000 milkings the levels of reddening and damage to the teat increase significantly. This form of damage to the cow's teat means it loses its natural resistance to bacteria and pathogens, leader to higher somatic cell count and incidents of mastitis.

So, it's easy to see that a disciplined approach to changing liners will help to ensure the health of your herd and quality of your milk and that trying to make liners stretch to a few more milkings is truly a false economy.

If you have any questions about liners or would like to order liners for your shed contact Nind Dairy Services on 0800 50 22 50 or email dairy@nind.co.nz.

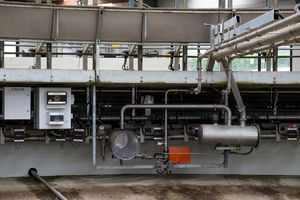

Milking machine testing explained

Milking machine is testing is now a requirement and for good reason. Machine malfunctions cause teat damage, increasing the risk of infection. Not to mention the downtime involved when the plant suddenly fails. An annual test by a registered milking machine tester at least once per season will help to keep things running smoothly.

So, what’s involved? Who can do it? And what to do with the results?

Logan Barnett explains what’s involved: “A milking machine test checks all the working components of the machine, ensuring everything works to the manufacturers’ specifications.

“Testers must be MPTA certified, so they carry out a standard test procedure which involves full visual inspection of the milking machine components, plus a full vacuum, leak and restriction test on vacuum operated components. Any deficiencies in the plant will show up in the written report.”

Your report will have three parts:

- Vacuum testing calculations and recordings;

- A visual report page, listing the components, each marked with a tick (pass) or cross (fail);

- A summary of recommendation telling you whats required to get the machine working back to full capacity.

There are a lot of numbers on the report which probably won’t mean much to farmers, says Logan.

Any deficiency is noted, whether minor, major or critical.

“It’s really important that you take action to address all the faults sooner or later, even those reported as minor because nine out of ten times, these will become major if disregarded.”

Logan stresses it’s imperative that to have a milking machine test at least once annually. “When you’re using the plant daily, you won’t notice things that slowly develop and change. This test picks up stuff like that immediately. Testing ensures your machine is operating well, while reducing the risk of mastitis and pre-empting failures in your equipment before they happen.”

KEY POINTS:

THE TEST:

Milking machine tests take 4-6 hours. The procedure involves a full visual inspection of the milking machine components, plus a full vacuum, leak and restriction test on vacuum operated components. Any deficiencies in the plant will show up in the written report.

THE BENEFITS:

- Peace of mind that the milking machine is working as it should

- Animal health problems may be traced to faults in the machinery

- Shows areas with need attention before you get a breakdown situation

If you have any questions or want to book a milking machine test contact the office on 0800 50 22 50.