Milking machine testing explained

19th May 2024

Rethink Cups On with iCR+ Intelligent Cluster Removers

19th November 2020

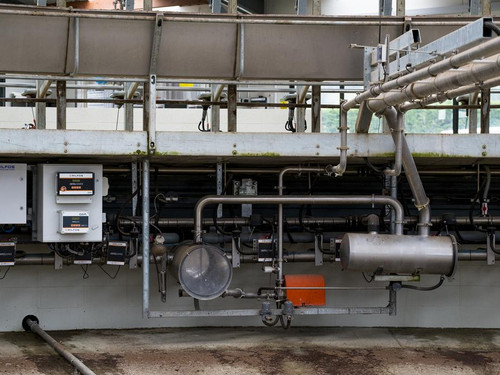

Need chilled milk? Nind can help.

19th November 2020

Draft cows your way with CowScout and the AS3000 Drafting Gate

19th November 2020

Want to monitor your cows your way? Get CowScout Collars.

19th November 2020

Get Milk Vat Monitoring sorted with Nind Dairy Services & HALO Systems

11th December 2019

Get an AquaCHILL unit retrofitted to ensure compliance

1st April 2019

Do you need a Nind Dairy Services Plumbing Warrant of Fitness?

21st February 2019

Book in a Shed Servicing

3rd December 2018

Summer is approaching - check your water supply

2nd December 2018